|

|

|||

| site search by freefind |

(If you don't see the Google Translate's "Select Language", then your browser is blocking google translate...so enable googleapis.com)

Last modified October 2, 2023Gottlieb Pinball Troubleshooting - ElectroMechanical games. Gottlieb Electro-mechanical (EM) games (relays...) Re: EM: Gottlieb Drum Unit problems Gottlieb Fast Draw not resetting properly ; most EM pins Setting up EM Drop Target banks

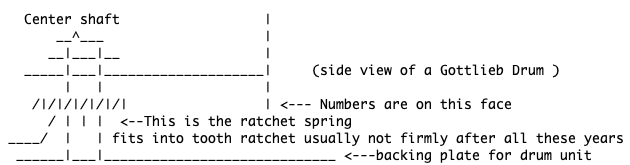

Electro Mechanical: Gottlieb Drum Unit problems TO: All Spotted this... GG> From: gig@n8pph27.nt.com (Gil Graybill) GG> Date: 21 Nov 1995 21:59:29 GMT GG> Some questions: GG> (A) About 90% of the time when a 50-point award is to be given, it's GG> worth 60 points. Can I do anything *reasonable* about this, or is that GG> just something that 30+ year old machines will do? Check for switch bounce on the timing motor and that the break contact on the drum unit is opening just before the plunger bottoms out. You might also have a ratchet spring on the drum unit that is not engaging the underside of the number drum. make sure that it is bent out and snaps into the stepped ratchet on the under side of the number drum. I don't think I can draw that in ASCII but I'll try....

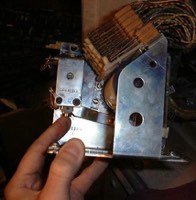

Note that I have left out the solenoid, springs, drive ratchet assembly and other stuff (you try drawing it smarty ;-) Hope this is clearer..... :-#)> Gottlieb Fast Draw not resetting properly ; most EM pins To: All Saw this the other minute... m> From: fido@inforamp.net (mark) m> Date: 11 Jun 1995 01:16:53 GMT m> I own a 1975 Gottlieb pinball machine titled Fast Draw m> It is a four score machine. The machine is in excellent condition. m> Everything works just fine except it does not give me my m> bonus score. I think because of this it will not indicate m> game over. Both of these problems are intermittent. With most EM games of any vintage, when a symptom of slow or intermittent operation shows up, first check the operation of the step up/down units that control the counts for Bonus, Ball, Player, etc. You will usually find that some misinformed person (read idiot) has used WD-40 as a (ha) lubricant (double ha). The problem with WD-40 is that after a couple of years it turns to glue. The moving parts must then be removed, soaked in varsol, polished and then reassembled using a good grade of oil. I use Zoom-Spout, but bicycle oil or sewing machine oil will work fine. Easy test is to operate the step-up plunger, it should snap back solidly with a solid thunk sound. The surface of the contact discs can be greased with coin machine lube or a light grease (any suggestions? as I use coin machine lube)(update 2006) Hi. Just began reading your informative web sit. Two things. First, I have read that using vaseline petroleum jelly is a terrible lubricant for the very few parts which we lubricate on pin machines. It turns hard later. Best substance for lubrication is electronic teflon lube gel, which is available at Radio Shack, etc. This gel is excellent for these few areas of lubrication. Second, I believe the teflon lube gel is ideal for steppers as well. This Signed, new interested reader protecting connectors from corrosion as well as reducing contact resistance and thus heat. Setting up EM/SS Drop Target banks The correct way to setup a Gottlieb drop target bank is to (after repairing any broken/missing targets/parts) press the plunger of the lift arm all the way to the bottom of the, being careful NOT to press on the lift bar itself. You are pretending to be the coil you see, and thus only the plunger is pressed in. Now with the plunger bottomed out in the coil, loosen the coil bolts (four of them) enough that you can slide the coil up/down the slots, and slide the coil to the point where all the targets have raised enough to JUST pass the catch bar by about 1/32nd of an inch (1mm). Now tighten the four screws, and double check the adjustment by dropping the targets and pressing the plunger home. This adjustment, if done properly, will reset the targets every time, yet not break off the small stop tab at the very bottom of the targets. If those are broken off, the targets are being lifted too much. Pictures to come... Gottlieb's Player Unit - Friend or Foe? (under construction...) Not for the first time have we worked on the Player Unit.

|

|||||||||

(jrr-at-flippers-dot-com for those who do not have their browser set to open their email client) |

Click here to order Parts

Click here to order Parts